Our primary mission is to revolutionize urban infrastructure through the adoption of a genuinely circular economy, underpinned by innovative technology that makes a tangible and positive impact on Climate.

The problem

+50 Billion tons of CO2e are sent to the atmosphere annually worldwide.

But today’s Carbon Sequestration solutions presented have issues that slow us down toward our 2030 goals:

The technologies available are too expensive to implement

The current solutions take too much time to deliver real results

Very few of them are able to fit in the city's current infrastructure

And even fewer of them have truly scalable capabilities

What to do

To get to our global climate goals, we need solutions that fit specific criteria

Must be cost-effective

Need to be fast to deploy/implement

Must generate results fast

Need to be easily implemented in the

city’s current infrastructure

Must be truly scalable worldwide

The Solution

We now present to you: Biogenix Carbon Sequestration Modular Reactor Plants

After 30+ years of academic studies and field analysis + 2 years of technology research, Biogenix brings to the world an innovative state of the art solution to help global efforts to control the Climate Change through our Carbon Sequestration Modular Reactor Plants.

The Innovation

In a race against time, a solution in hand

Our Plants are rapidly implemented and in 12 to 18 months they’ll be fully operational.

Our Reactor Plants are modular, which allows them to be easily optimized to scale according to the demand without interfering in the production process.

Also, the Plant’s design is planned to fit seamlessly into the city’s waste treatment current infrastructure.

Fast implementation through modules

Designed to fit into the city’s infrastructure

Cost-effective - optmized capex and opex

Scalable worldwide

The Technology

A new way to look at waste

In our Plants, we’ll produce in industrial scale one of the most efficient carbon sequestration mechanisms to store CO2 into the soil forever: Biochar.

Biochar is the final product of the process called pyrolysis, where the biomass, enriched with nutrient and organic matter, is heated in high temperatures without oxygen inside reactors.

The biomass contains at least half of its weight in the form of Carbon e it will be extracted and stabilized to create the biochar.

Biochar is basically all the carbon extracted from the atmosphere by the plants through photosynthesis and transformed in a very stable form of Carbon.

To every ton of biochar produced, it’s possible to compensate for 2 tons of CO2 emitted by other industries.

Carbon Sequestration

done right

Biochar is the most effective solution to store CO2e into the soil at a stable and definitive way.

The Impact

Redesigning waste management cycle infrastructure

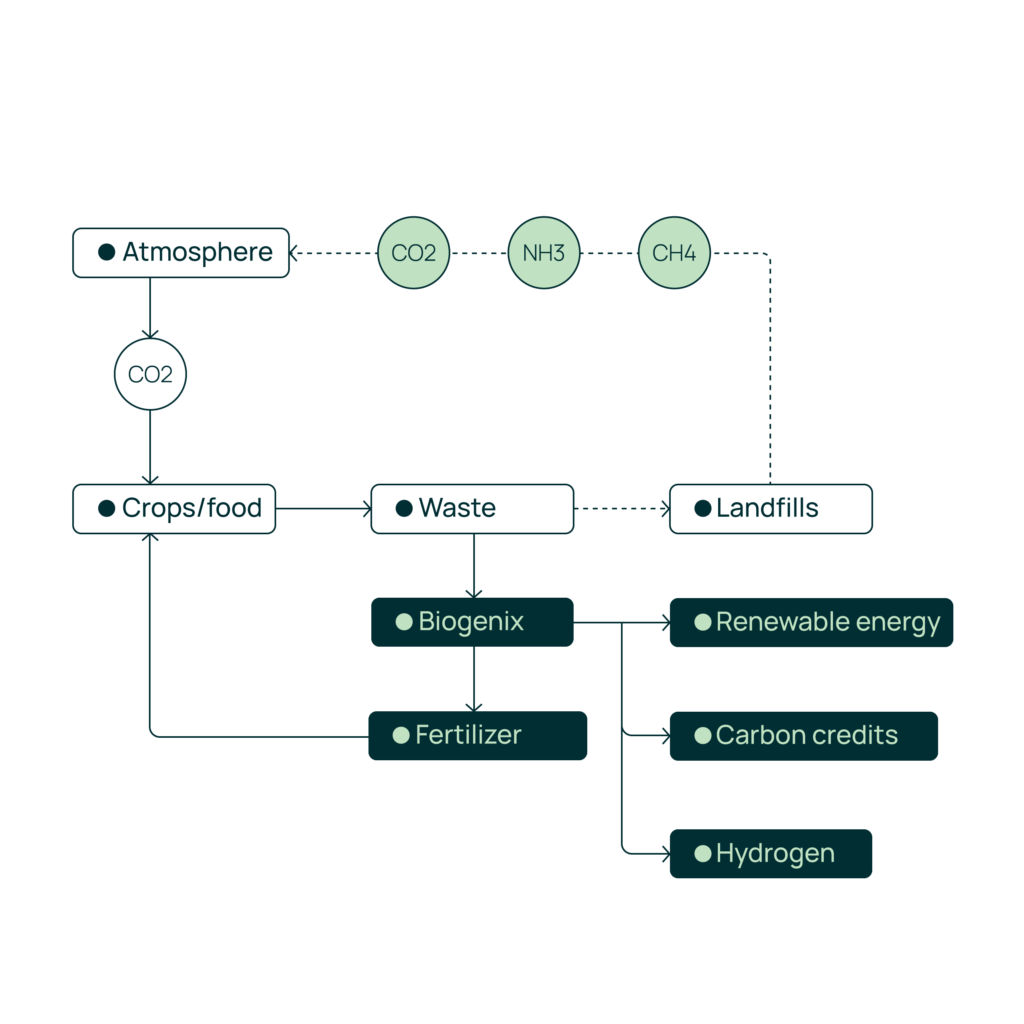

When food becomes waste, it goes to the urban wastewater treatment processes, where it’s in the form of sludge and every CO2 that the plant extracted from the atmosphere during its life, is released back to it, alongside with other greenhouse gasses, like Ammonia, Methane, Nitrous oxide and others.

That’s because most of the sludge in every major city around the world is sent to landfills, and during this process is where the greenhouse gas emissions occur.

Emissions from landfills and the sanitation industry reached 5.2 gigatonnes of CO2 equivalent in 2022, accounting for approximately 3.3% of total greenhouse gas emissions.

Our Plants will be able to produce at industrial scale organomineral fertilizers, biochar, renewable energy (biomethane) and generate carbon credits at one place.

We’ll implement our Plants inside the current urban and industrial wastewater treatment cycle as a cleaner and noble solution, considerably reducing emissions.

Also, our model doesn’t fit exclusively in the city’s sanitation infrastructure, our Plants can be placed in areas close to (or inside) industries, farms and ethanol plants, that want to neutralize their emissions.

Our team

Meet the Biogenix leadership team committed to a greener tomorrow

Our team getter together more than 40 decades of experience in this field, with other projects implemented all over the world.

Osvaldo Schimitt

CEO

Cássio Piccinini

Founder & COO

Regina Lana

Head of Fertilizer Dept. and Production Engineer

Neuton Ribeiro

Head of Engineer, Innovation and Process

Project status

Biogenix #1 Modular Reactor Plant current status

In our pursuit of urban transformation, we're committed to not only fostering cleaner and more affordable energy solutions but also enhancing health and food security for people across the globe, aligning with 10 out of the United Nations' 17 Sustainable Development Goals.